Search

Additional Links Contact Us- Phone: (800) 423-4198

- Toll-Free: (815) 885-1900

- Email: [email protected]

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn more

In the dynamic world of packaging, pouch machines offer the best flexibility and efficiency. For packaging professionals and business owners navigating this arena, understanding the pivotal role of fillers in pouch machine operations is crucial. Whether you’re stepping into the packaging field or looking to optimize your existing operations, this guide sheds light on the different types of pouch machine fillers, their uses, and upcoming trends.

Pouch machines have revolutionized the packaging industry by offering an array of solutions for packing products in pouches with precision and speed. They’re versatile, capable of handling different materials, and adjustable to various sizes and shapes of pouches. This adaptability makes pouch packaging machines an asset for businesses across the food, pharmaceutical, and cosmetic sectors, among others. The integration of fillers in pouch machines further amplifies their efficiency, enabling accurate and consistent filling of products into pouches.

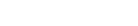

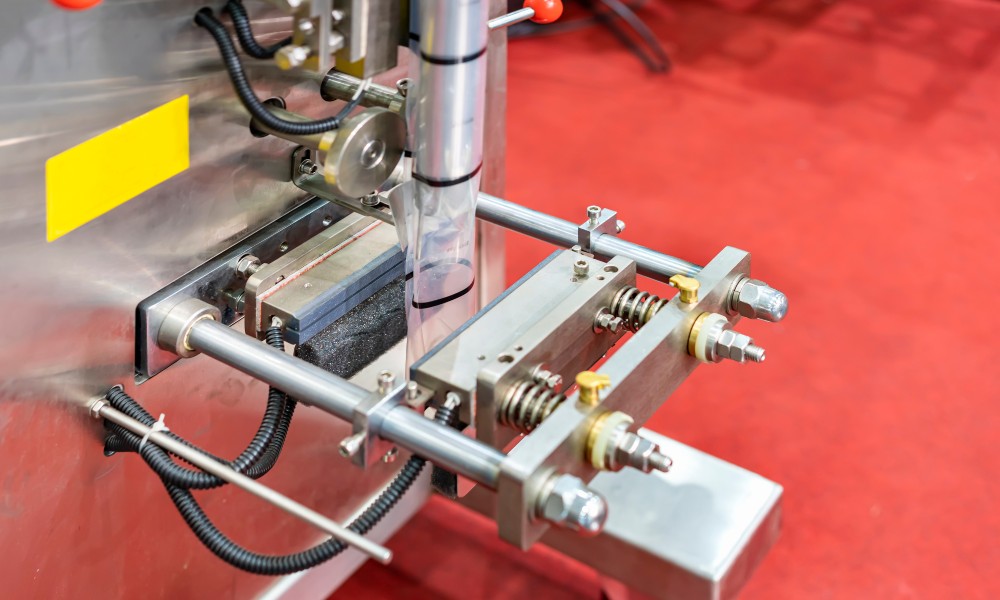

Fillers are the heart of pouch machines, determining the efficiency of the packaging process and the integrity of the product. They ensure the correct amount of product goes into each pouch, maintaining consistency and quality. The choice of filler type impacts sealing effectiveness, speed, and suitability for the product’s physical characteristics. Therefore, understanding the various filler types and their uses is crucial for optimizing pouch machine operations.

With so many different types of pouch packaging machines, you should know what each is for, as well as its advantages and disadvantages.

Manufacturers design liquid fillers specifically for handling liquids ranging from water-thin to very viscous products. They’re ideal for beverages, sauces, chemicals, and pharmaceutical liquids. It’s possible to gravity-feed or pump liquid fillers depending on the product’s characteristics and packaging requirements. With precise control over filling volume, liquid fillers are essential for minimizing waste and achieving accurate pouch filling.

Manufacturers use powder fillers for packaging products in powder form, such as spices, flour, or pharmaceutical powders. They rely on an auger or vacuum to accurately dispense the product. Auger-based fillers are ideal for free-flowing powders, while vacuum-based fillers work best for non-free-flowing powders. Powder fillers can handle a wide range of packaging sizes and offer high flexibility in terms of product variety.

Granule fillers are optimal for products that are in granule form, such as coffee, sugar, or grains. These fillers use volumetric or weight-filling methods to ensure consistency. Volumetric filling is ideal for uniform granules, while weight-filling offers greater accuracy for irregularly shaped granules. Granule fillers can handle high-speed packaging and offer versatility in packing multiple types of products.

Piece-count fillers are perfect for products that need packaging in specific counts, such as candies, hardware items, or capsules. These fillers use a counting mechanism to ensure each pouch contains the desired number of pieces. They’re highly accurate and efficient, allowing for fast and precise packaging.

Multi-head weigh fillers are the go-to solution for mixed or complicated products that require high accuracy and speed. These fillers use multiple weigh heads to ensure each pouch is the correct weight, making them perfect for snack foods, mixed candies, and frozen foods. Multi-head weigh fillers are highly efficient, reducing packing time and increasing production rates.

Vacuum fillers work well for products that are challenging to handle due to their nature, such as fresh meats, poultry, or certain dairy products. These fillers remove the air from the pouch before filling it with the product, extending the product’s shelf life by reducing oxidation and bacteria growth. Vacuum fillers are crucial in the food industry, especially for packaging products that are sensitive to air exposure.

Selecting the appropriate filler involves understanding your product’s physical properties, desired packaging speed, and accuracy requirements. Consider product flow characteristics, the potential for air entrapment, and the need for sanitary design. Consulting an experienced packaging supplier can help ensure compatibility and optimize performance. Additionally, being aware of current and upcoming trends in pouch machine fillers can also inform your decision.

Successful filler implementation begins with thorough product testing, considering environmental factors and potential interactions with packaging materials. Collaborating with machinery suppliers can provide valuable insights into optimizing your packaging line. Regular maintenance and training employees on proper operation can prolong equipment life and maximize efficiency. Additionally, keeping up with advancements in filler technology and industry trends can help you stay ahead of the competition.

Pouch machine fillers are continuously evolving, driven by the demands of diverse industries and consumer preferences. Staying informed and adaptable to these trends can ensure your business remains competitive and efficient in the ever-changing packaging landscape. Here are some future trends to be aware of:

These advancements promise even greater precision, flexibility, and environmental stewardship.

The landscape of pouch machine fillers is vast and varied, with each different type bringing distinct benefits to the table. This means horizontal form fill seal machine manufacturers can help you ensure your products arrive fresh and in good condition. By understanding the nuances of each, businesses can significantly enhance their packaging operations, ensuring product integrity and satisfaction.